Conveyor, Vibrating

Highest Possible Production.

Lowest cost per ton

in the Industry.

Lorem ipsum dolor sit amet.

Conveyor, Vibrating

Capabilities

All components are heavy-duty as the spherical roller bearings used in the drive section. Motor under the conveyor gives added protection. Contact the factory for custom sizes, vibrating tables, various custom widths and screening sizes. Options include: chipper transitions, fiberglass sections for metal detector use, sawdust drop outs and wear liners.

Main frame for the heavy-duty unit is made from 6” channel at 16.3 pounds per foot. The vibrating conveyor’s energy is transferred through the heavy-duty fiberglass support bars to the heavy-duty channel. This secure footing reduces maintenance and insures long life.

Sawdust removal screen allows only blocks, slabs and edgings to enter the chipper, increasing chipper blade effectiveness and reducing dust. Sawdust discharge is custom, and user specified.

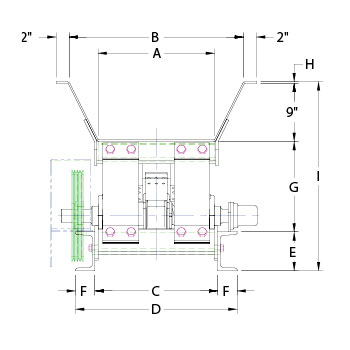

- A18" [457mm]

- B27" [686mm]

- C15.5" [394mm]

- D19 1/4"[489]

- E5" [127mm]

- F1 7/8" [48mm]

- G7 3/4" [197mm]

- H3/16" [5mm]

- I21 3/4" [552mm]

- A24" [610mm]

- B33" [838mm]

- C15.5" [394mm]

- D19 1/4" [489mm]

- E5" [127mm]

- F1 7/8" [48mm]

- G7 3/4" [197mm]

- H3/16" [5mm]

- I21 ¾” [552mm]

- A18" [457mm]

- B27" [686mm]

- C19" [483mm]

- D25" [635mm]

- E6" [152mm]

- F3" [76mm]

- G14" [356mm]

- H1/4" [6mm]

- I29" [737mm]

- A24" [610mm]

- B33" [610mm]

- C19" [483mm]

- D25" [635mm]

- E6" [152mm]

- F3" [76mm]

- G14" [356mm]

- H1/4" [6mm]

- I29" [737mm]