Round Wood Chippers

Highest Possible Production.

Lowest cost per ton

in the Industry.

Lorem ipsum dolor sit amet.

Round Wood Chippers

- Chipper Size 75" [190 cm]

- Chipper Size 84" [213cm]

- Chipper Size 96" [244 cm]

- Chipper Size 112" [284 cm]

- Chipper Size 118" [300 cm]

- Number Of Knives3-8

- Weight15,000 lbs. [6,804 kg]

- R.p.m. Of Disc560

- Thickness Of Disc5 7/8” [149 mm]

- Production (tons/hr.)125 [113 mt]

- Number Of Knives3-8

- Weight24,500 lbs. [11,113 kg]

- R.p.m. Of Disc510

- Thickness Of Disc5 7/8” [149 mm]

- Production (tons/hr.)175 [159 mt]

- Number Of Knives4-10

- Weight33,100 [15,014 kg]

- R.p.m. Of Disc450

- Thickness Of Disc5 ⅞” [149 mm]

- Production (tons/hr.)250 [227 mt]

- Number Of Knives6-10

- Weight44,200 [20,049 kg]

- R.p.m. Of Disc360

- Thickness Of Disc5 7/8” [149 mm]

- Production (tons/hr.)300 [272 mt]

- Number Of Knives6-12

- Weight52,000 [23,587 kg]

- R.p.m. Of Disc327

- Thickness Of Disc5 ⅞” [149 mm]

- Production (tons/hr.)350 [318 mt]

Capabilities

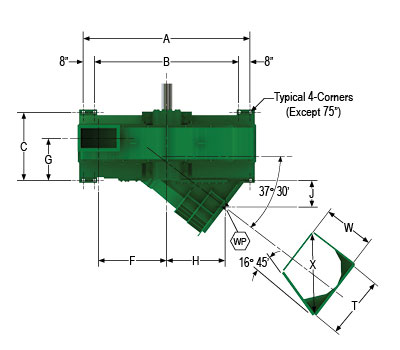

Precision's spout design with a flat bottom and canted side gives 25% more anvil contact with the log. This provides absolute control of the log, preventing slapping and wood turning. Both horizontal and vertical anvils give additional life with less maintenance. Both are hard surfaced with colmonoy which has a hardness of 62 to 65 on the Rockwell C scale.

The canted side spout design and the position of the knife causes a smooth slicing action. The attack angle of the knife gives a gentle lift to the slab as the knife passes the center line and begins the upward swing turning the slab counterclockwise. The spout has a flat bottom and canted side to give 25% more anvil contact, preventing slapping and wood turning in the wrong direction. Horizontal and vertical anvils give additional life, requiring less maintenance. Both anvils are hard surfaced with colmonoy with a hardness of 62-65, Rockwell C scale. With a four-sided replaceable anvil, maintenance and time are saved. Less horsepower is needed with Precision’s smoother slicing action.

Options

Horizontal Feed

Rechipper Spout

Disc Brake

Drop or Gravity Feed

Helical Wear Plates

Left Hand or Right Hand

Bottom Discharge

Wear Liners

Hydraulic Hood Opener

Top / Bottom Discharge

Carbide Anvils

Belt Driven

Parallel / End Discharge

Two piece Hood

Direct Driven

Cardbreakers

One piece Hood

Dissipator for Rear Discharge Chippers

Hard Surfaced Counter Knives

- Chipper Size 75" [190 cm]

- Chipper Size 84" [213cm]

- Chipper Size 96" [244 cm]

- Chipper Size 112" [284 cm]

- Chipper Size 11" [300 cm]

- A75 ¼” [1911 mm]

- B75 ¼” [1911 mm]

- C39” [991 mm]

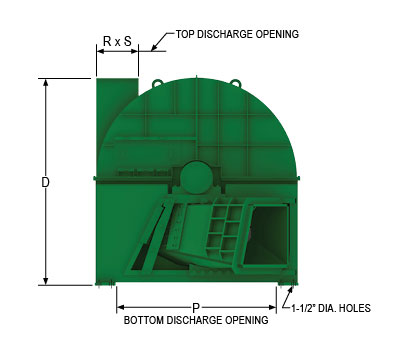

- D82 ⅝” [2099 mm]

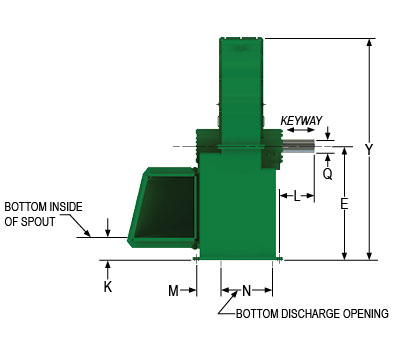

- E43 ⅛” [1095 mm]

- F31 ⅜” [797 mm]

- G22 ⅜” [568 mm]

- H34” [864 mm]

- J12” [305 mm]

- K10 ¼” [260 mm]

- L13 ⅛” [333 mm]

- M10 ¼” [260 mm]

- N25 ¼” [641 mm]

- P63 ¼” [1607 mm]

- Q5 3/16” [132 mm]

- R9 ¾” [248 mm]

- S16” [406 mm]

- T27” [686 mm]

- W22” [559 mm]

- X35” [889 mm]

- Y85” [2159 mm]

- KEYWAY1 ¼” x ⅝” x 13” [32 mm x 16 mm x 330 mm]

- A88 ½” [2248 mm]

- B72 1/2” [1842 mm]

- C43” [1092 mm]

- D93 3/4” [2381 mm]

- E46 11/16” [1186 mm]

- F34 3/8” [873 mm]

- G24 1/2” [622 mm]

- H43 5/8” [1108 mm]

- J19 1/2” [495 mm]

- K9 1/2” [241 mm]

- L15” [381 mm]

- M11 7/8” [302 mm]

- N27 ¼” [692 mm]

- P68 1/2” [1740 mm]

- Q5 7/16” [138 mm]

- R11” [279 mm]

- S20” [508 mm]

- T33” [838 mm]

- W26” [660 mm]

- X40” [1016 mm]

- Y97 3/4” [2483 mm]

- KEYWAY1 ¼” x ⅝” x 12” [32 mm x 16 mm x 305 mm]

- A100 ½” [2553 mm]

- B84 1/2” [2146 mm]

- C43” [1092 mm]

- D108 1/4” [2750 mm]

- E55 1/2” [1410 mm]

- F40 3/8” [1026 mm]

- G24 1/2” [622 mm]

- H45 1/4” [1149 mm]

- J21” [533 mm]

- K12 3/4” [324 mm]

- L17” [432 mm]

- M12” [305 mm]

- N27 1/2” [699 mm]

- P80 1/2” [2045 mm]

- Q6 15/16” [176 mm]

- R11” [279 mm]

- S20” [508 mm]

- T35 1/4” [895 mm]

- W27” [686 mm]

- X44” [1118 mm]

- Y111” [2819 mm]

- KEYWAY1 1/2” x 3/4” x 15 1/2” [38 mm x 19 mm x 394 mm]

- A117” [2972 mm]

- B101” [2565 mm]

- C49” [1245 mm]

- D123” [3124 mm]

- E63” [1600 mm]

- FN/A

- GN/A

- H51 1/2” [1308 mm]

- J23” [584 mm]

- K13” [330 mm]

- L21 11/16” [551 mm]

- M15 1/2” [394 mm]

- N29 1/2” [749 mm]

- P97” [2464 mm]

- Q8” [203 mm]

- RN/A

- SN/A

- T42” [1067 mm]

- W32” [813 mm]

- X53” [1346 mm]

- Y125” [3175 mm]

- KEYWAY1 3/4” x 7/8” x 15 1/2” [44 mm x 22 mm x 394 mm]

- A120” [3048 mm]

- B104” [2642 mm]

- C49” [1245 mm]

- D131 3/4” [3346 mm]

- E67” [1702 mm]

- FN/A

- GN/A

- H51 1/2” [1308 mm]

- J23” [584 mm]

- K13 1/4” [337 mm]

- L21 11/16” [551 mm]

- M15 1/2” [394 mm]

- N29 1/2” [749 mm]

- P100” [2540 mm]

- Q8” [203 mm]

- RN/A

- SN/A

- T45” [1143 mm]

- W36” [914 mm]

- X57 1/2” [1461 mm]

- Y138” [3505 mm]

- KEYWAY1 3/4” x 7/8” x 15 1/2” [44 mm x 22 mm x 394 mm]